The Ultimate Guide to Aluminum Alloy Cutting Saw Blades: Precision, Efficiency, and Durability

Aluminum alloy is widely used in industries such as aerospace, automotive, construction, and electronics due to its lightweight, corrosion-resistant, and high-strength properties. To achieve precise and efficient cutting of aluminum alloys, choosing the right cutting saw blade is essential. This article will explore the advantages, applications, and key factors to consider when selecting aluminum alloy cutting saw blades, helping you make the best decision for your cutting needs.

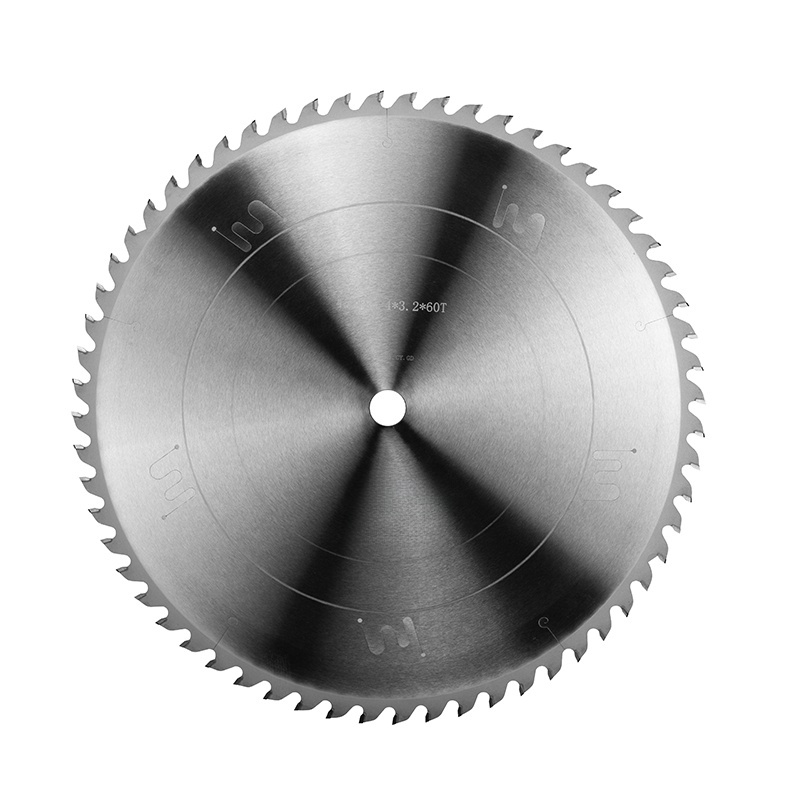

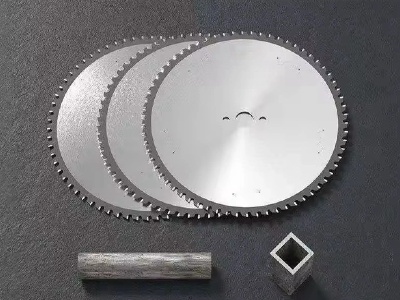

1. What Are Aluminum Alloy Cutting Saw Blades?

Aluminum alloy cutting saw blades are specialized tools designed to cut aluminum and other non-ferrous metals with high precision and efficiency. Unlike regular saw blades, these blades are specifically engineered to handle the unique challenges of cutting aluminum, including reducing heat buildup, preventing material distortion, and achieving smooth, burr-free cuts.

2. Advantages of Aluminum Alloy Cutting Saw Blades

1.1 High Precision Cutting

Aluminum alloy cutting saw blades provide precise and accurate cuts, ensuring smooth edges and minimal burr formation. This precision is crucial for industries that require high-quality finishes for aluminum parts, such as the automotive and aerospace sectors.

1.2 Increased Durability and Longevity

These blades are typically made from carbide-tipped materials or high-speed steel, making them durable and capable of withstanding the wear and tear of continuous cutting. The durability ensures a longer lifespan, reducing the need for frequent blade replacements and lowering operational costs.

1.3 Reduced Heat Generation

One of the key challenges when cutting aluminum alloys is heat buildup, which can cause material distortion and poor finishes. High-quality aluminum alloy cutting saw blades are designed to dissipate heat effectively, ensuring that the blade remains cool during operation, preventing overheating and ensuring clean cuts.

1.4 Smooth Surface Finish

Aluminum alloy cutting blades are designed to produce a smooth surface finish, minimizing the need for additional finishing processes. This is particularly beneficial for applications in the automotive and aerospace industries, where precise tolerances and smooth surfaces are critical.

3. Applications of Aluminum Alloy Cutting Saw Blades

3.1 Automotive Industry

Aluminum alloys are widely used in the automotive industry due to their lightweight properties, which improve fuel efficiency. Cutting saw blades designed for aluminum alloy applications are essential for producing high-quality parts, such as engine components, body panels, and wheels.

3.2 Aerospace and Aviation

In the aerospace industry, aluminum alloys are used for various parts of aircraft due to their strength-to-weight ratio. Precision cutting saw blades ensure that parts such as fuselage components, wings, and structural parts are cut with accuracy and minimal wastage.

3.3 Construction and Architecture

Aluminum alloys are commonly used in the construction of window frames, doors, and roofing materials. Aluminum alloy cutting saw blades are ideal for cutting through these materials with precision, improving the overall quality of the finished products.

3.4 Electronics Manufacturing

The electronics industry uses aluminum alloys in the production of heat sinks, housings, and other components. Efficient cutting of these materials is crucial to maintain product integrity and quality. Aluminum alloy cutting saw blades offer the precision and durability required for these delicate tasks.

4. How to Choose the Right Aluminum Alloy Cutting Saw Blade

4.1 Blade Material

When selecting an aluminum alloy cutting saw blade, the material of the blade is critical. Carbide-tipped blades are often the best choice as they offer excellent cutting performance and durability. For heavy-duty applications, high-speed steel (HSS) blades may also be suitable.

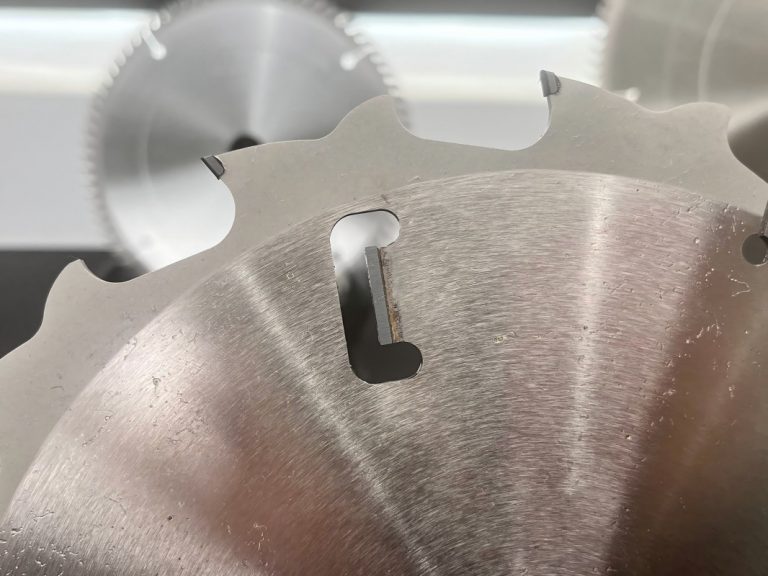

4.2 Blade Design

The design of the blade, including its tooth geometry and the number of teeth, plays a significant role in cutting efficiency. Blades with a higher tooth count are ideal for making smoother cuts, while those with fewer teeth can handle faster, rougher cuts.

4.3 Cutting Speed and Feed Rate

Selecting the right cutting speed and feed rate is essential for achieving the best performance. A saw blade that operates at the optimal speed will provide better precision and reduce the likelihood of overheating or blade wear.

4.4 Coatings and Surface Treatments

Some aluminum alloy cutting saw blades come with special coatings such as titanium nitride (TiN) or anti-stick coatings to reduce friction, prevent material buildup, and extend the life of the blade.

5. Maintenance Tips for Aluminum Alloy Cutting Saw Blades

To maximize the lifespan and performance of your aluminum alloy cutting saw blades, proper maintenance is crucial. Here are a few tips:

- Regular Cleaning: Clean the blade after each use to remove any buildup of aluminum material, which can affect cutting performance.

- Inspect for Damage: Regularly inspect the blade for any signs of wear or damage, such as chipped or dull teeth, which can affect the quality of the cut.

- Proper Storage: Store the blades in a dry and cool environment to prevent rust and corrosion.

6. Conclusion

Aluminum alloy cutting saw blades are essential tools for industries that rely on precision and efficiency in cutting aluminum and other non-ferrous metals. With advantages like high precision, durability, reduced heat generation, and smooth surface finishes, these blades are the go-to solution for a wide range of applications, including automotive, aerospace, construction, and electronics.

By understanding the key features and selecting the right blade for your specific needs, you can improve cutting performance, reduce operational costs, and ensure the highest quality results. Whether you are a manufacturer or a contractor, investing in quality aluminum alloy cutting saw blades is a smart choice to stay ahead in a competitive market.