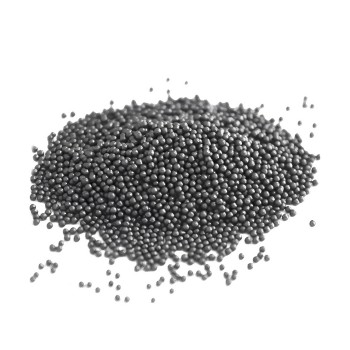

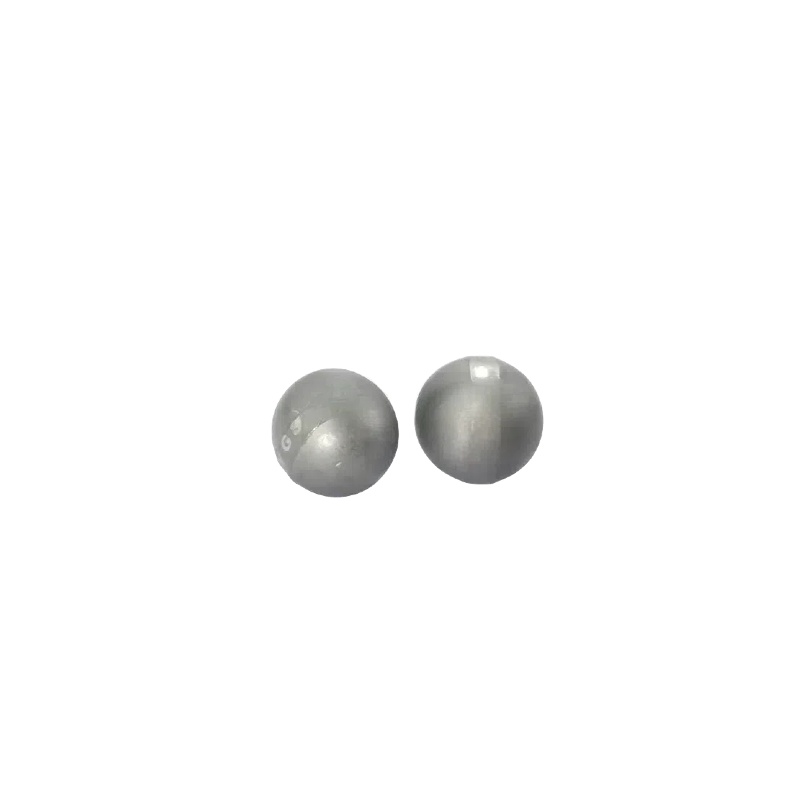

Tungsten Carbide Pellets For Welding Oil Drilling And Mining Tools

KY Carbide Tungsten Carbide Pellets used for Hardbanding new and used drill pipe collars.The main application for tungsten carbide pellets is their use as high-performance cutting tools. They are commonly used in machining, grinding, and sawing applications.

描述

Tungsten Carbide Pellets

Tungsten carbide is a very hard and dense material, is used in tools and cutters requiring high hardness and cutting resistance. It is also used to make wear-resistant cutting knives and drills. This material is made by sintering tungsten carbide powder in a hot mixture of carbon and silicon carbide (SiC) powders at temperatures up to approximately 2,400 degrees Celsius (4,000 degrees Fahrenheit).

In addition to granules, tungsten carbide powder is also often commercially available because the powder form is more suitable for certain industrial applications, including the production of cutting tools and other abrasives.

Industries that primarily use tungsten carbide pellets include manufacturing, metallurgy, mining and mechanical engineering.

Application

1:Tungsten carbide pellets are used as reservoir balls for oil shale mining operations and as abrasives in ceramics manufacturing processes.

2:Cutting tool-Tungsten carbide pellets are used as cutting tools for metals, plastics and other materials. It can be used to cut hard materials such as stainless steel, titanium, and nickel alloys.

3:Semiconductor production-Tungsten carbide pellets are used as semiconductor materials in integrated circuit (IC) manufacturing. It provides high thermal conductivity, high strength and excellent mechanical properties, which are important for semiconductors.

4:Abrasives-Tungsten carbide powder is often used as an abrasive for stamping grinding. Excellent wear resistance and long service life at high speeds.

5:KY Carbide Tungsten Carbide Pellets used for Hardbanding new and used drill pipe collars

| Grade | Densityg/cm3 | HardnessHRA | TRS ≥N/mm² |

| KY3 | 14.5-14.7 | 90.0-91.0 | 1700 |

| KY4 | 14.6-14.7 | 91.0-91.5 | 1700 |