Cold Saw vs. Regular Saw Blade: Which One is Right for Your Cutting Needs?

When it comes to cutting tough materials like high carbon steel, choosing the right saw blade is crucial to ensuring precision, durability, and efficiency. Whether you’re in the metalworking industry, automotive sector, or any other field that requires cutting hard metals, you need to decide between a cold saw blade and a regular saw blade. In this blog, we’ll break down the differences between these two types of saw blades, helping you make an informed decision for your next cutting project.

What is a Cold Saw Blade?

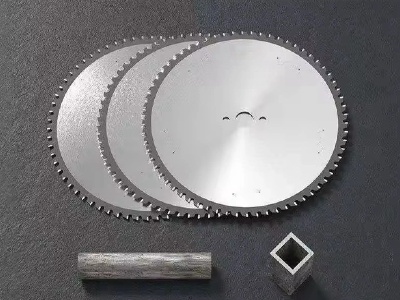

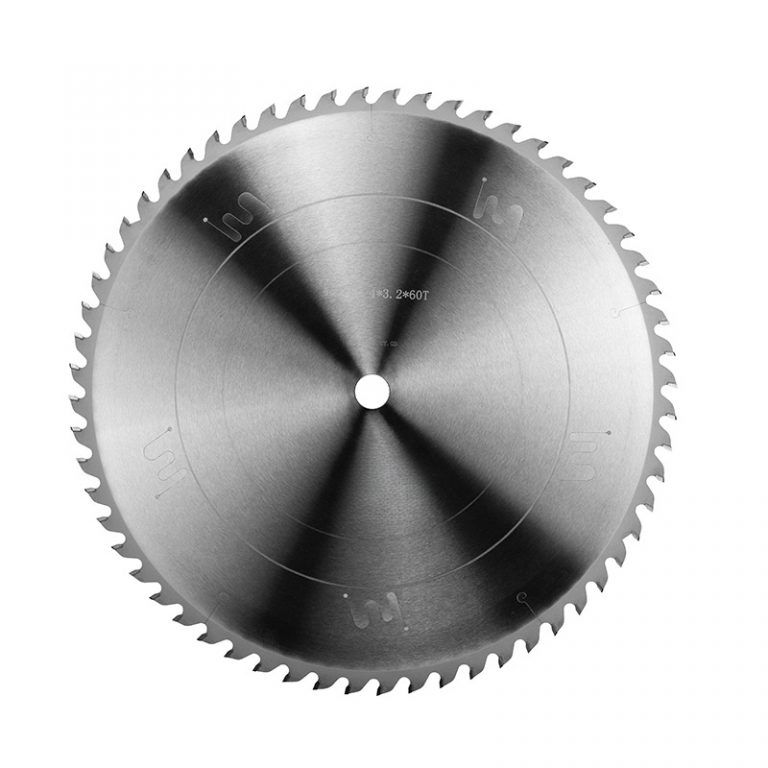

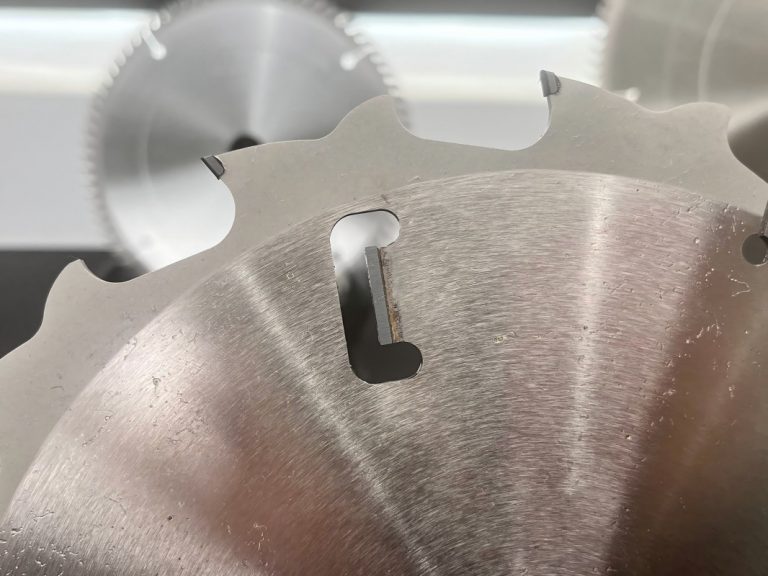

A cold saw blade is a specialized cutting tool designed to cut through metals with minimal heat generation. Unlike traditional saw blades, cold saws operate using a slow, rotating circular blade made from high-quality materials like high-speed steel (HSS) or carbide. The slow cutting speed ensures that the heat generated during the cutting process is minimal, which helps preserve the material’s integrity.

Advantages of Cold Saw Blades:

- Clean, Smooth Cuts: Cold saw blades produce precise, clean cuts with minimal burrs and heat distortion. This makes them ideal for applications where high-quality, precise cuts are essential.

- Reduced Heat Build-Up: One of the most significant advantages of cold saws is their ability to cut with minimal heat. This prevents material from warping or discoloring, which is especially crucial when working with high carbon steel or other heat-sensitive metals.

- Longer Tool Life: Since cold saw blades don’t generate excessive heat during cutting, they experience less wear and tear. This means that cold saw blades generally have a longer tool life compared to regular saw blades.

- Ideal for Tough Materials: Cold saws are specifically designed for cutting tough materials such as high carbon steel, stainless steel, alloys, and non-ferrous metals, making them a go-to choice for industrial applications in industries like automotive, construction, and metalworking.

- Better Precision: With the ability to make precise cuts and minimal distortion, cold saw blades are perfect for applications where high accuracy is required, such as structural cutting or precision machining.

What is a Regular Saw Blade?

A regular saw blade, on the other hand, is a general-purpose cutting tool used for a variety of materials, such as wood, plastic, and light metals. These blades are typically designed to operate at higher speeds, generating more friction and heat during the cutting process.

Advantages of Regular Saw Blades:

- Faster Cutting Speed: Regular saw blades are designed to operate at higher speeds, which makes them more efficient for cutting softer materials like wood, plywood, and plastic.

- Cost-Effective: Regular saw blades are generally more affordable than cold saw blades, making them a good option for everyday cutting tasks, particularly in woodworking and light-duty metalworking.

- Versatile: Regular saw blades are versatile and can be used for a wide range of materials. Whether you’re cutting wood, plastic, or non-ferrous metals, regular saw blades are a reliable option for most general cutting needs.

- Ideal for Softer Materials: Regular saw blades are perfect for woodworking and plastic cutting, as well as light-duty cutting in the construction and DIY sectors.

Cold Saw Blade vs. Regular Saw Blade: Key Differences

| Feature | Cold Saw Blade | Regular Saw Blade |

|---|---|---|

| Cutting Speed | Slower, more controlled cutting | Faster cutting speed |

| Heat Generation | Minimal heat buildup | Higher heat generation |

| Cut Quality | Clean, smooth, and precise cuts | Rougher cuts, especially in metals |

| Material | Ideal for hard metals like high carbon steel | Best for softer materials like wood or plastic |

| Durability | Longer tool life due to less wear | May wear faster due to higher friction |

| Applications | Metalworking, automotive, structural cutting | Woodworking, plastic cutting, light metals |

When to Use a Cold Saw Blade:

- When you need to cut through hard metals like high carbon steel, stainless steel, or alloys.

- When precision and clean cuts are required, such as in structural or machining applications.

- When working in industrial settings where heat buildup could damage materials.

- For long-term use where tool life and efficiency are key considerations.

When to Use a Regular Saw Blade:

- When cutting softer materials such as wood, plastic, or non-ferrous metals.

- For quick, general-purpose cuts where precision is not as critical.

- When working on DIY projects, woodworking, or construction tasks that don’t require specialized tools.

- For budget-friendly cutting solutions that don’t require the durability or precision of a cold saw blade.

Conclusion: Which Blade is Right for You?

Choosing between a cold saw blade and a regular saw blade depends on the material you’re cutting and the precision you require. If you’re working with tough metals and need clean, accurate cuts with minimal heat, a cold saw blade is your best bet. However, if you’re cutting softer materials and speed is more important than precision, a regular saw blade will be sufficient for your needs.

Understanding these differences can help you choose the right blade for your specific application, ensuring you get the best results every time.