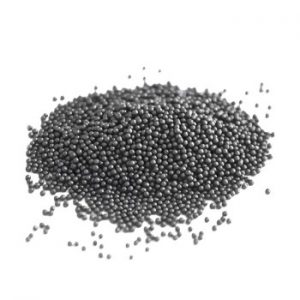

Carbide Beveling Heads Raw Materials Blanks

A beveling cutter head blank is the initial, unshaped material that will be further processed or machined into a cutting tool, such as a beveling head, typically used in metalworking operations. These blanks are often made from tungsten carbide or other carbide alloys and are used to form the final cutting tool, which is typically attached to a machine to bevel, chamfer, or edge metal workpieces.

描述

Carbide beveling cutter heads blanks are the raw material used to create precision beveling tools for metalworking, specifically designed to create beveled edges on metal surfaces. Carbide is a highly durable material known for its extreme hardness, wear resistance, and ability to withstand high cutting temperatures, making it ideal for creating bevel heads that will endure tough machining conditions.

A beveling cutter head blank is the initial, unshaped material that will be further processed or machined into a cutting tool, such as a beveling head, typically used in metalworking operations. These blanks are often made from tungsten carbide or other carbide alloys and are used to form the final cutting tool, which is typically attached to a machine to bevel, chamfer, or edge metal workpieces.

Key Properties of Carbide as a Raw Material:

Key Properties of Carbide as a Raw Material:

- Hardness: Carbide is one of the hardest materials known, making it highly effective for cutting tough materials like stainless steel, high-alloy metals, and hardened tool steels.

- Wear Resistance: Carbide is resistant to abrasive wear, which is essential for tools that undergo repeated use, especially in demanding metalworking applications.

- Heat Resistance: Carbide can withstand high temperatures generated during the cutting process without losing its hardness, making it suitable for high-speed cutting operations.

- Brittleness: While carbide is incredibly hard, it can be brittle and prone to chipping if not handled carefully during machining or in high-impact operations.

Carbide Beveling Cutter Head Applications

Carbide beveling cutter heads made from blanks are used in various metalworking applications, including:

- Beveling Edges: Creating beveled edges on metal parts to prepare them for welding, assembly, or aesthetic purposes.

- Chamfering: Producing chamfered or angled edges on metal components for fitting, joining, or assembly.

- Deburring: Carbide beveling tools are often used to remove burrs or sharp edges from cut metal workpieces.

- High-Precision Metalworking: Carbide bevel heads are used in industries like aerospace, automotive, and manufacturing, where precision and durability are key.