Why Carbide Bevel Heads Blanks Are the Best Choice for Precision Metal Cutting: A Wholesaler’s Guide

Introduction: The Power of Carbide Bevel Heads Blanks in Metal Cutting

When it comes to metal cutting tools, carbide bevel heads blanks stand out for their precision, durability, and high performance. As a wholesaler in the industrial tools sector, we understand the critical need for cutting tools that deliver consistent, accurate results while reducing maintenance costs. This blog explores why carbide bevel heads blanks are a superior choice for metalworking applications and how they can enhance the performance of your cutting operations.

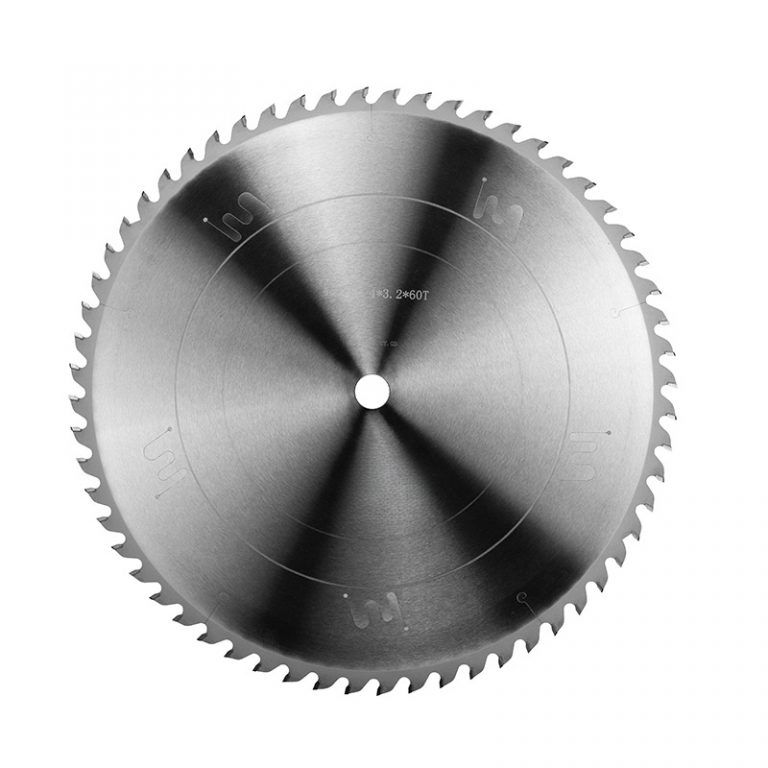

1. What Are Carbide Bevel Heads Blanks?

Carbide bevel heads blanks are the raw, unshaped material used to create beveling tools for metalworking. These blanks are made from tungsten carbide, a material known for its extreme hardness and wear resistance. They are essential for creating cutting tools that can produce beveled edges on metal workpieces with high precision.

Key Benefits of Carbide Bevel Heads Blanks:

- Increased Tool Life: Carbide tools last significantly longer than those made from traditional tool steels.

- Precision Cutting: Carbide provides a sharp, consistent cutting edge, ensuring clean bevels and reducing the need for post-processing.

- High-Speed Performance: Carbide handles high cutting speeds, allowing for faster and more efficient operations.

2. Why Choose Carbide for Beveling Cutter Heads?

As a wholesaler, we understand that your customers rely on durable, high-performance tools. Carbide bevel heads blanks provide the following advantages for metal cutting applications:

2.1 Superior Hardness and Wear Resistance

Carbide’s extreme hardness allows bevel heads to withstand abrasive conditions, making them perfect for cutting through tough materials like stainless steel, titanium, and alloy metals. The wear resistance of carbide means your cutting tools stay sharper longer, reducing the frequency of replacements and downtime.

2.2 Heat Resistance

Carbide tools can maintain their hardness even at high temperatures generated during high-speed cutting. This is particularly beneficial for applications that require prolonged, continuous cutting.

2.3 Improved Cutting Precision

The hardness of carbide allows for precision beveling, ensuring consistent and clean edges. This reduces the need for secondary finishing processes, saving time and improving overall productivity.

3. Applications of Carbide Bevel Heads Blanks in Metalworking

Carbide bevel heads blanks are ideal for various metalworking applications, especially where precision and durability are paramount. Some common uses include:

3.1 Beveling for Welding Preparation

Carbide bevel heads are frequently used to create beveled edges on metal parts in preparation for welding. A clean, well-defined bevel ensures a strong weld joint and minimizes the risk of defects.

3.2 Chamfering and Edge Finishing

In addition to beveling, carbide bevel heads can be used for chamfering edges on parts to create angled cuts for easier assembly or aesthetic purposes.

3.3 Deburring

Carbide bevel heads are effective in removing burrs and sharp edges left from the cutting process, ensuring safer handling of metal parts.

3.4 Precision Machining

Carbide bevel heads are essential for precision machining in industries like aerospace, automotive, and manufacturing, where exact tolerances are critical.

4. How Carbide Bevel Heads Improve Efficiency and Reduce Costs

As a wholesaler, offering carbide bevel heads blanks can significantly benefit your customers by improving their production efficiency and reducing operational costs. Here’s how:

4.1 Reduced Downtime

With carbide’s long tool life and superior cutting performance, your customers will spend less time replacing worn tools and more time focusing on production.

4.2 Higher Cutting Speeds

Carbide bevel heads perform well at higher speeds, which increases overall productivity. This is particularly useful in high-volume production environments where time is of the essence.

4.3 Lower Maintenance Costs

Carbide’s durability means fewer tool replacements and repairs, translating to lower maintenance costs for your customers over time. They can invest in fewer tools, reducing their overall tooling budget.

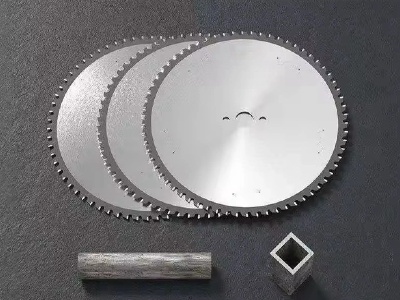

5. Choosing the Right Carbide Bevel Heads Blanks for Your Business

As a wholesaler, offering the right carbide bevel heads blanks is essential to meeting the needs of your customers. Here are a few factors to consider when selecting the right carbide bevel heads:

5.1 Material Type

Carbide is effective for cutting a wide range of metals, including steel, stainless steel, aluminum, and non-ferrous metals. Ensure that the carbide tool is compatible with the materials your customers are working with.

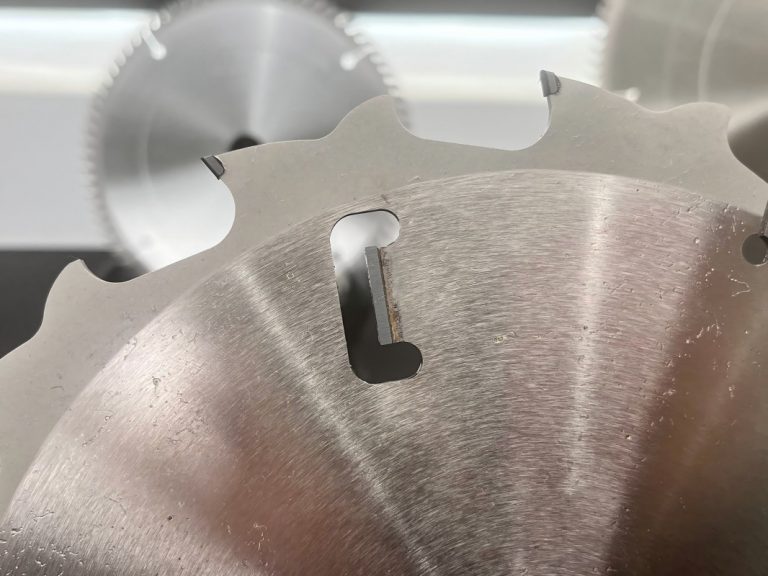

5.2 Coatings

Many carbide bevel heads are coated with materials like Titanium Nitride (TiN) or Titanium Carbonitride (TiCN) to improve performance. These coatings enhance the wear resistance, reduce friction, and improve the lifespan of the cutting tool.

5.3 Size and Shape

Carbide bevel heads come in different sizes and shapes depending on the application. Offering a range of sizes can help you cater to a variety of customer needs, from large-scale industrial manufacturing to precision machining.

6. Conclusion: The Value of Carbide Bevel Heads Blanks for Wholesalers

As a wholesaler of industrial cutting tools, offering carbide bevel heads blanks allows you to provide your customers with high-performance tools that deliver precision, durability, and long-term cost savings. Carbide’s hardness, wear resistance, and heat resistance make it an ideal material for beveling and cutting applications in industries like automotive, aerospace, and general manufacturing.

If you’re looking for high-quality carbide bevel heads blanks at wholesale prices, reach out to us today for competitive rates and expert advice on choosing the right tools for your needs.